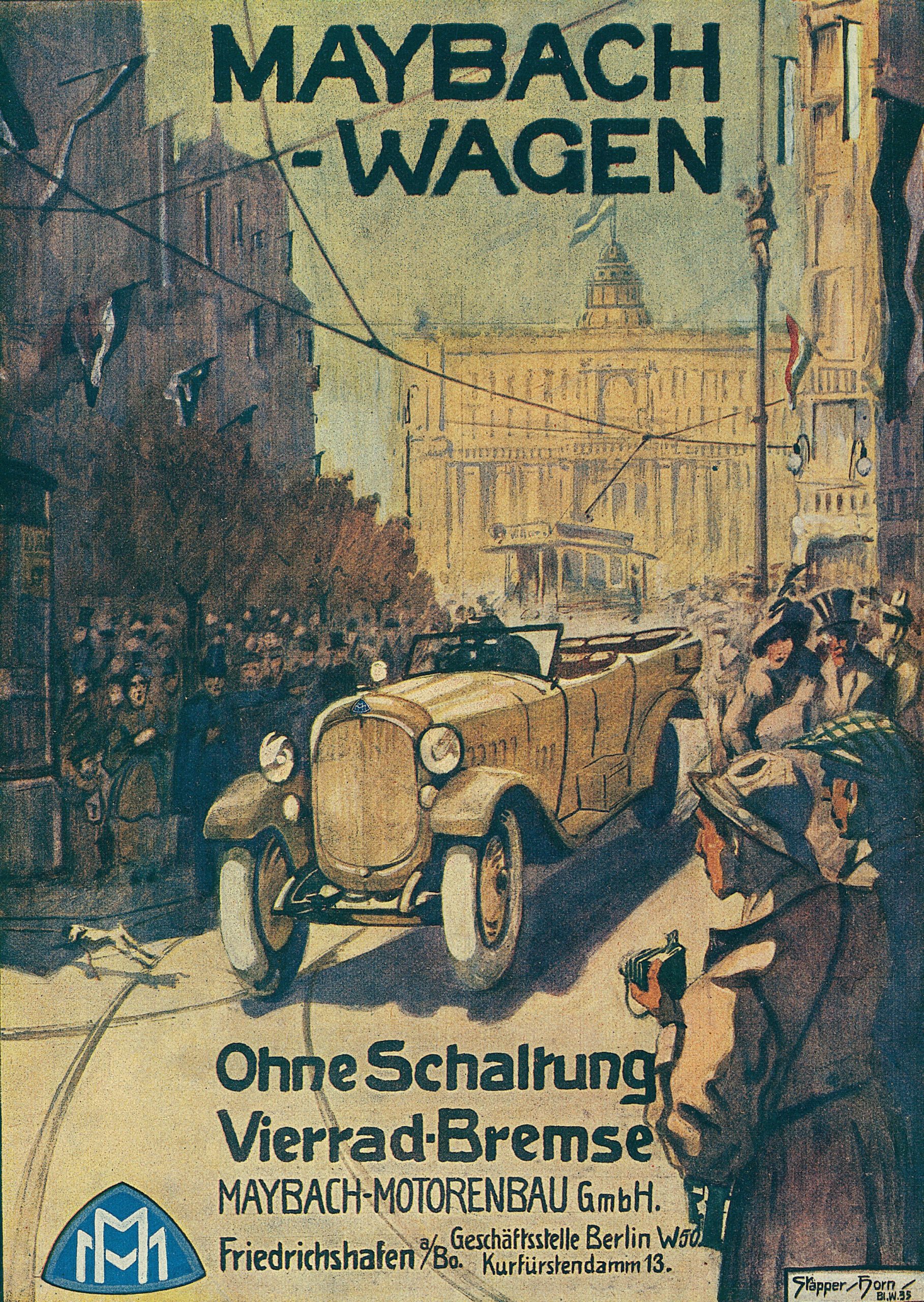

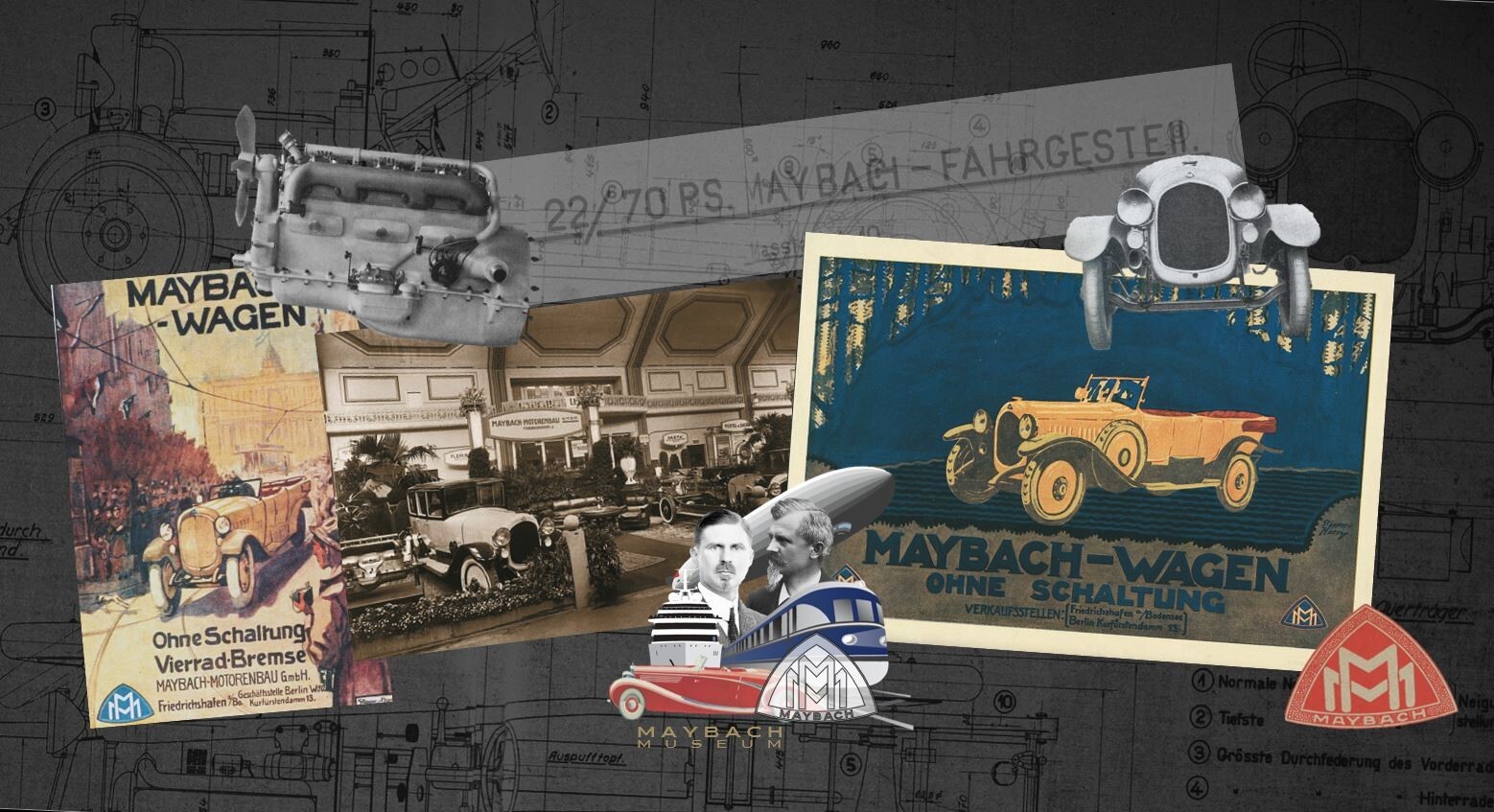

Today we are presenting a recently acquired, iconic image of an original advertisement for the 22⁄70 PS Maybach car that we today know under its designation W 3 (‘W’ is short for the German word ‘Wagen’ = vehicle/car). The year 2021 sees the 100-year-anniversary of its launch – a fitting occasion to look into the pretext that led to the original Maybach cars being built in Friedrichshafen at the Maybach Motor Works.

WWI meant a ceasura to world history and when it ended, it had left many parts of the world devastated. The impact on global markets and economies was likewise drastic. For Maybach Motor Works it meant that the area in which they had proven their competence, was now prohibited. The Versailles treaty of 1919 stated that all production of aerial machinery in Germany shall cease. However, it was clear, that the company’s capacities in constructing and manufacturing high-performance engines could also be applied to other applications, one of which was automobiles. Karl Maybach, who oversaw Maybach Motor Works, had developed a racing car engine in France that served as the base for the developments of aerial propulsion. His father Wilhelm Maybach had done groundbreaking work which culminated in the first Mercedes in 1901 which defined the shape of the modern automobile.

In 1919 the W 1 type engine was installed in a Daimler touring car bought from military surplus and was combined with a newly developed cooler mask, essentially giving the vehicle a ‘face’ — the first Maybach test vehicle had seen the light of day. This car was given the same designation as the engine it was using – “W 1” — and though photographic documents exist, the original is lost without a trace. Having further enhanced the W 1 type engine to 70 horsepower and labeling it W 2, the Maybach Motor Works set out looking for a partner to supply the newly developed car engine to. Trompenburg, a Dutch manufacturer was chosen. The car they marketed became known as Spijker Tenax, the latter meaning ‘tenacious’. Indeed, the product managed to achieve some success, with victories at several endurance rides, one of which was the successful completion of a 30,000 km journey through the snowy Netherlands at which the Spijkter beat an older record set by Rolls Royce. Despite this promising start, the coöperation soon came to an end as Trompenburg filed for bankruptcy. Meanwhile, in Friedrichshafen, there was now a backlog of engines that were ready to be used – but the partner would not install or pay for them, only 150 of 1000 ordered were used. It was this twist of fate that led to Maybach cars being built in Friedrichshafen at Maybach Motor Works.

Back then cars were often manufactured as chassis, onto which a bodywork was installed. This was also the path taken at Maybach Motor Works but now a chassis needed to be developed. The task was quickly taken up and completed not much later. One would expect the W 1 car to be followed by a W 2 model, but interestingly no such vehicle is known to have existed. The first Maybach Car in serial production got the designation W 3. It used an enhanced W 2 type engine and was presented in 1921 at the IAA (Internationale Automobil Ausstellung = International Automobile Exhibition) Berlin from the 23rd of September to the 2nd of October. Delivering 70 horsepower already at 2200 revs., it was met with good resonance by the press and the public as it combined the Maybach quality standard with new technical intricacies. Two of these are mentioned on our advertising page: ‘Ohne Schaltung’, meaning ‘without gear shift’ and ‘Vierrad-Bremse’ meaning ‘four-wheel break’. The first meant that due to the engine’s elasticity, the car used only two gears which could be shifted via a foot lever. As a result the driver rarely had to take his or her hands off the steering wheel. Another innovation was embedding the mechanism for the horn into the door – the driver thereby could use it with his or her forearm. The four-wheel brake system mentioned above, which had been developed at Maybach, made driving a safer endeavor and was for the first time used in a serial car in Germany. These innovations effectivity further enhanced driving comfort as it lessened the need to shift gears. Maybach cars were never produced in large numbers because they were top-notch products in terms of reliability, quality, and performance and they were correspondingly expensive. Sadly, none of the remarkable W 3 series has survived. The chassis by itself cost a whopping 24,000 Reichsmarks and an additional 15 to 25,000 had to be added, depending on what kind of body was to be installed. For reference: the average yearly salary in 1924 was 1,233 Reichsmarks. The cars that followed the W 3, such as the twelve Cylinder models Maybach 12 and DS 7 and 8, are legends to this day still — a hundred years after the story began.

Leave a Reply